When a fire rages through a home, it doesn’t just leave ash and char-it leaves behind a smell that clings to walls, floors, and ceilings. No amount of scrubbing can fully remove it. The same goes for pet urine soaked into concrete, trauma scenes, or mold creeping through drywall. These aren’t surface problems. They’re odor migration problems. And that’s where odor encapsulation comes in.

Forget air fresheners. Forget masking scents with sprays. Odor encapsulation isn’t about hiding smells. It’s about trapping them-permanently. This isn’t magic. It’s science. And it’s become a non-negotiable step in professional biohazard cleanup, fire restoration, and water damage recovery.

What Exactly Is Odor Encapsulation?

Odor encapsulation is the process of applying a specialized coating that seals in odor-causing molecules so they can’t escape into the air. Think of it like putting a lid on a jar full of rotten food. The smell doesn’t vanish-it’s locked away. But unlike plastic wrap, these coatings are engineered to bond with building materials: wood, drywall, concrete, metal, even HVAC ducts.

The key difference between a regular sealer and an odor encapsulant? Timing and purpose. A sealer goes on after you’ve cleaned everything up. An encapsulant goes on over unremoved contaminants. That’s why you’ll see encapsulants used over asbestos or lead paint-because removal isn’t safe or practical. But in fire or biohazard cleanup, you clean first, then encapsulate. You don’t seal in dirt-you seal in what’s left behind after the dirt is gone.

Why Traditional Sealers Fail

Old-school sealers like shellac used to be the go-to for smoke odor. Made from insect resin dissolved in alcohol, shellac works-sort of. It blocks smells well. But it also blocks vapor. And that’s a problem.

Buildings need to breathe. Walls, especially in basements or bathrooms, let moisture escape naturally. When you slap a shellac sealer over drywall, you trap moisture inside. That’s how mold grows behind the paint. That’s how wood rots. That’s why restoration pros stopped using it for everything.

Shellac is like a brick wall. Modern water-based sealers? They’re more like a fine mesh screen. They let water vapor pass through but stop odor molecules. One manufacturer compares it to a pasta strainer: water flows out, but the noodles (odor molecules) stay trapped.

The Rise of Water-Based Encapsulants

Today’s gold standard? Water-based, low-VOC, zero-VOC sealers. These products contain no harsh solvents, don’t off-gas toxic fumes, and clean up with soap and water. That matters because you’re often working in occupied homes or businesses. You can’t have workers or residents breathing in fumes while you’re trying to fix the problem.

Here’s what makes them better:

- No VOCs - No volatile organic compounds means no chemical smell during or after application.

- Vapor-permeable - Allows moisture to escape, preventing mold and rot.

- Single-coat effectiveness - Many modern formulas block odors with just one pass.

- Flexible and durable - Won’t crack or peel over time like older products.

These aren’t just marketing claims. They’re backed by real-world results. Restoration companies in Portland, Chicago, and Atlanta now report fewer callbacks and fewer mold complaints after switching to water-based encapsulants.

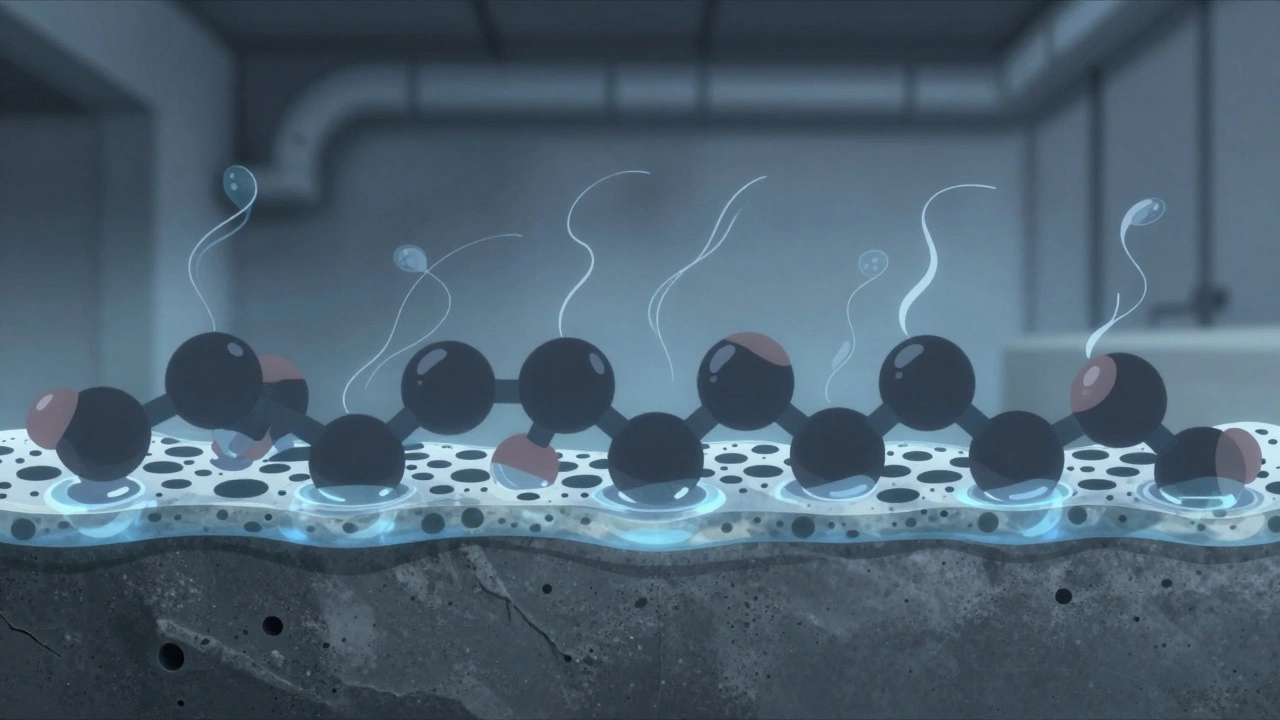

How It Works: The Science Behind the Seal

Odor molecules are tiny-often smaller than water vapor. But encapsulants aren’t just thick paint. They’re engineered with molecular filters built into the coating. As the sealer dries, it forms a network of microscopic pores. These pores are small enough to block odor molecules (which are larger and heavier) but large enough to let water vapor through.

Products like RECON Smoke Odor Sealer by Fiberlock Technologies use a patented tech called OdorLock. It doesn’t just sit on top-it bonds deep into the substrate. That means even if humidity rises or temperatures drop, the seal holds. No reactivation. No smell creep.

Sentinel 537 and Sentinel 538 from Senpro work similarly. They’re clear, low-viscosity liquids that spray on thin and dry fast. They’re used after professional cleaning with products like Sentinel 531 or Sentinel 522. You don’t skip the cleaning step. You do it first. Then you seal.

Bioesque Solutions takes it further. Their product has the highest solids content in the industry-meaning more material per coat. One layer does the job of two or three older products. It’s tintable, so you can match wall colors. And it includes built-in antimicrobial protection, stopping mold from growing on the sealed surface itself.

Where It’s Used: Beyond Fire Damage

Most people think of fire when they hear "odor encapsulation." But it’s used everywhere odors stick:

- Fire damage - Smoke odor trapped in drywall, insulation, and wood framing.

- Pet urine - Especially on concrete floors, subfloors, or baseboards.

- Trauma scenes - Biological contamination from accidents or violence.

- Mold remediation - After mold is removed, encapsulants prevent residual odors from returning.

- Water damage - Musty smells from flooded basements or leaky pipes.

- Commercial spaces - Warehouses, garages, gyms, and restaurants with grease or chemical odors.

Concrete is one of the toughest substrates to treat. It’s porous. Odors sink deep. But specialized concrete odor sealers penetrate up to 1/4 inch below the surface, locking in molecules before they ever reach the air. These are the same products used in industrial facilities, parking garages, and basements where regular paint fails within months.

Application: It’s Not a DIY Job

You can’t just buy a can of spray paint and call it done. Proper application makes or breaks the result.

- Clean first - No sealer works if the surface still has residue. Use odor counteractants like Sentinel 531 or Bioesque’s cleaner before sealing.

- Use the right tool - Airless sprayers deliver even coverage. Foggers work for hard-to-reach areas. Brushing or rolling creates uneven layers that leak odor.

- Watch the height - For ceilings over 15 feet, use dry-fall formulas like Sentinel 540. Dried overspray falls as powder and sweeps away-no ladder work needed.

- Let it cure - Most products need 24-48 hours to fully bond. Don’t rush it.

Professional crews use moisture meters, infrared cameras, and air quality monitors to confirm the odor is gone before sealing. Skipping steps leads to failure. And failure means the smell comes back-and the client blames you.

Why This Matters for Biohazard Cleanup

In biohazard cleanup, odor isn’t just unpleasant-it’s a sign of lingering contamination. Blood, bodily fluids, decomposition: these leave behind volatile organic compounds that can trigger nausea, headaches, or even respiratory issues. Sealing them in isn’t just about comfort-it’s about health.

Antimicrobial-enhanced encapsulants like Sentinel 539 are designed for this. They don’t just block odor-they stop mold and mildew from growing on the sealed surface. That’s critical after trauma scenes or sewage backups, where residual moisture invites microbial growth.

Regulatory agencies are catching up. Many states now require low-VOC products in occupied buildings. Insurance adjusters are asking for proof of encapsulation before approving claims. Restoration standards are shifting. This isn’t an optional step anymore. It’s part of the protocol.

What’s Next?

The next wave of odor encapsulation is smarter. Products are being developed to:

- React to humidity changes and tighten their seal automatically

- Include odor-neutralizing agents that break down molecules, not just trap them

- Work on new surfaces like composite decking, vinyl siding, and painted metal

- Be certified for use in hospitals and schools

One lab in Ohio is testing a formula that changes color when it’s fully cured-giving crews instant visual confirmation. Another is integrating UV-reactive markers so inspectors can verify coverage under blacklight.

But the core hasn’t changed. Clean. Seal. Verify. Repeat. The technology just got better.

Can I use odor encapsulation on my own after cleaning up a pet urine stain?

You can, but only if you’ve done a full cleanup first. Enzymatic cleaners break down urine crystals. If you skip that step, the odor will return. Use a water-based sealer like Bioesque or Sentinel 537. Apply with a sprayer for even coverage. Don’t roll it on-it won’t penetrate well. Let it dry 48 hours before walking on it. If the smell comes back, you didn’t clean deeply enough.

Do I need to remove drywall after a fire?

Not always. If the drywall isn’t charred or structurally damaged, you can clean it with a smoke odor counteractant, then seal it with a product like Sentinel 538. Professionals test for soot penetration with a blacklight and moisture meter. If the soot is only on the surface, sealing works. If it’s soaked in, removal is necessary. Never seal over uncleaned soot-it traps toxins.

Are water-based sealers as strong as shellac?

In odor blocking? Yes. In vapor blocking? No-and that’s the point. Shellac blocks everything, which causes moisture damage. Modern water-based sealers block odors while letting vapor pass. That’s why they’re safer and more durable long-term. Shellac is like a plastic bag over a plant. Water-based sealers are like breathable fabric. The plant thrives.

Can I paint over odor encapsulants?

Yes, absolutely. Most are designed as primers. Once fully cured (usually 24-48 hours), you can apply latex or oil-based paint over them. Some, like Bioesque’s product, are tintable so you can use them as a final coat. Just make sure the sealer is dry before painting. If it’s still tacky, the paint will peel.

What’s the difference between an encapsulant and a sealer?

Encapsulants go over unremoved contaminants-like asbestos or heavy soot-to contain them. Sealers go on after cleaning, to prevent odors from returning. In fire cleanup, you clean first, then seal. In asbestos abatement, you encapsulate because removal isn’t safe. They’re not interchangeable. Using the wrong one can make the problem worse.