When you're working with chemicals in a drug analysis lab, one mistake can cost you more than time-it can cost you your health. There’s no such thing as "just a quick mix" when you're dealing with acutely toxic compounds, carcinogens, or reproductive hazards. Every day, labs across the country handle substances that can cause permanent damage if not managed with precision. The difference between safety and disaster isn’t luck-it’s a written plan, proper gear, and a culture that treats every chemical like it’s dangerous because it is.

Why This Isn’t Just About Rules

OSHA’s Laboratory Standard (29 CFR 1910.1450) has been around since 1990, but it’s not outdated. It’s the baseline. Every lab that handles hazardous chemicals-whether it’s analyzing street drugs, forensic samples, or pharmaceuticals-must have a Chemical Hygiene Plan (a written program outlining policies, procedures, and responsibilities to protect workers from chemical hazards). This isn’t a document you file and forget. It’s a living system. Every year, it must be reviewed and updated. If your lab hasn’t touched it since 2020, you’re already out of compliance.More than half of lab incidents happen because someone skipped the risk assessment before starting work. A 2022 American Chemical Society report found that 37.2% of chemical exposures came from experiments that weren’t properly planned. That means someone opened a bottle, poured it into a flask, and thought, "This shouldn’t be a problem." It always is.

Engineering Controls: Your First Line of Defense

You can’t rely on gloves or goggles alone. The best protection is built into the room. A properly functioning chemical fume hood (a ventilated enclosure designed to capture and exhaust hazardous vapors) is non-negotiable. For general work, the minimum airflow at the face of the hood must be 100 feet per minute. For Particularly Hazardous Substances (chemicals classified as acutely toxic, select carcinogens, or reproductive toxins), that number jumps to 150 feet per minute. If your hood doesn’t meet that, it’s not safe to use.And don’t just assume your hood works. Every lab should have a certification log. Hoods are tested annually for airflow, and if the numbers are below standard, they’re taken out of service. No exceptions. You also need proper ventilation in the lab overall. ANSI/ASSP Z9.5-2022 says labs handling highly toxic substances need 12 to 15 air changes per hour. If your lab smells like solvents even after hours, your ventilation isn’t cutting it.

Personal Protective Equipment: What You Actually Need

Gloves, goggles, lab coats-yes. But not just any gloves. Not just any goggles. The right gear depends on the chemical. Safety Data Sheets (16-section documents that detail chemical hazards, handling, and emergency procedures) are your guide. Specifically, look at Section 8: Exposure Controls and Personal Protection. It tells you what glove material works for what chemical.For example, nitrile gloves protect against many organic solvents but fail against acetone. Latex is useless against most lab chemicals. You need to check compatibility charts every time you handle something new. A 2023 Triumvirate audit found that 48% of glove-related incidents were due to using the wrong material. That’s not ignorance-it’s negligence.

Eye protection? Safety glasses with side shields aren’t enough anymore. If you’re working with volatile or splash-prone substances, full-face shields are required. Lab coats? Must be chemical-resistant, buttoned up, and never worn outside the lab. No exceptions.

Storage: Keep the Wrong Things Apart

Storing chemicals haphazardly is a recipe for disaster. The NFPA 400 (Hazardous Materials Code that defines segregation standards for incompatible chemicals) is clear: acids go away from bases. Oxidizers away from flammables. Water-reactive materials away from moisture. And Particularly Hazardous Substances (chemicals classified as acutely toxic, select carcinogens, or reproductive toxins) must be stored in secondary containment-like a spill tray or a ventilated cabinet with a sealed bottom.One lab in Oregon had a fire because someone stored perchloric acid next to organic solvents. Perchloric acid + organics = explosion. That incident was avoidable. The storage area had no labels, no segregation plan, and no inspection logs. Your chemical inventory should be updated weekly. A 2023 survey of academic labs found that 68.4% had outdated or incomplete inventories. If you don’t know what you have, you can’t manage the risk.

Waste and Spills: Don’t Wait Until It’s Too Late

Spills don’t wait for business hours. Your lab must have a spill kit for every hazard class-and you must know how to use it. For Particularly Hazardous Substances (chemicals classified as acutely toxic, select carcinogens, or reproductive toxins), you need a dedicated spill response protocol. That includes containment, neutralization, and disposal through authorized hazardous waste channels. Never pour chemicals down the drain unless the SDS says it’s safe. And even then, check local regulations.Waste containers must be labeled, sealed, and stored in a designated area. Vacuum systems used to clean up PHS must have HEPA filters. One lab in California was fined $75,000 because they used a regular shop vac to clean up a mercury spill. Mercury vapor doesn’t just disappear. It lingers. And it builds up.

Training: It’s Not a One-Time Box to Check

Training isn’t a PowerPoint you watch once a year. OSHA requires that workers know how to detect hazardous chemicals, understand their health effects, and know how to protect themselves. That means hands-on training. Drills. Practice. MIT reduced disposal costs by 27.3% by tracking chemical usage patterns-not because they bought better equipment, but because they trained staff to use less.Quarterly safety drills cut incident rates by 63.8% compared to labs that trained only once a year. That’s not a suggestion. That’s data. Your principal investigator must approve work with toxic gases or pyrophorics before you even order them. And you need documented instruction from someone experienced before you handle those materials. No "just watch me"-you need to demonstrate competency.

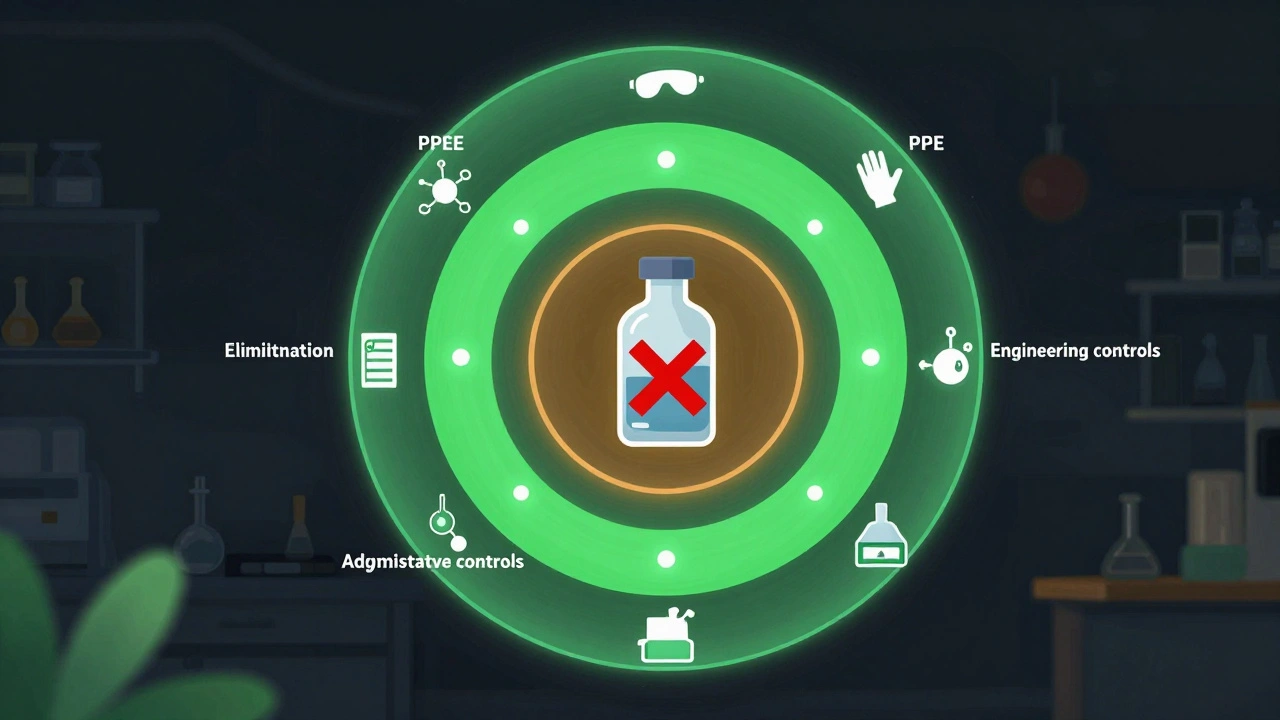

The Bigger Shift: Safety Starts Before You Open the Bottle

The biggest change in lab safety over the last five years isn’t new gear-it’s new thinking. The hierarchy of controls (a system prioritizing elimination, substitution, engineering, administrative, and PPE as last resort) is now embedded in experimental design. The most effective labs don’t ask, "How do we protect ourselves from this chemical?" They ask, "Can we use a safer alternative?"78.6% of research institutions now require hazard assessments before any experiment is approved. That’s up from 42% in 2020. The American Chemical Society is rolling out a standardized risk assessment tool in 2026 to reduce the 61.2% variability in how labs evaluate risk today. That means you won’t be able to wing it anymore. You’ll need to fill out a form, check off hazards, and get approval before you even turn on the stir plate.

And it’s working. The number of labs with dedicated chemical hygiene officers rose from 82.3% in 2020 to 98.7% in 2025. That’s not coincidence. It’s culture.

What’s Next? Nanomaterials and Complex Hazards

The next frontier isn’t just chemicals. It’s combinations. Labs now handle experiments that mix biological agents, radiological materials, and hazardous chemicals. These multi-hazard scenarios accounted for 22.4% of non-compliance findings in 2025. The CDC’s NIOSH is finalizing guidelines for nanomaterial exposure monitoring, with updates expected in Q3 2026. Why? Because 147 incidents involving engineered nanomaterials were reported in 2024-2025 alone.And then there’s CRISPR-related research. New compounds are being created faster than safety protocols can catch up. That’s why the National Academies’ 2025 update to "Prudent Practices in the Laboratory" emphasized behavioral safety: 83% of incidents were caused by human error-not equipment failure.

So ask yourself: Are you just following rules? Or are you building a culture where safety is the default?

What is a Chemical Hygiene Plan (CHP) and why is it required?

A Chemical Hygiene Plan (CHP) is a written program required by OSHA’s Laboratory Standard (29 CFR 1910.1450) that outlines policies, procedures, and responsibilities for protecting workers from hazardous chemicals. It must include standard operating procedures, criteria for determining when PPE is needed, engineering controls, employee training, and procedures for handling Particularly Hazardous Substances. It’s required because it’s the only way to ensure consistent, enforceable safety practices across all lab activities. Every lab using hazardous chemicals must have one, update it annually, and train staff on its contents.

What counts as a Particularly Hazardous Substance (PHS)?

According to OSHA, a Particularly Hazardous Substance includes chemicals that are acutely toxic (Category 1 or 2 under GHS), select carcinogens (like benzene or formaldehyde), or reproductive toxins (like lead acetate or ethylene glycol ethers). These require enhanced controls: dedicated work areas, secondary containment, specific labeling ("DANGER, AUTHORIZED PERSONNEL ONLY"), and mandatory SOPs. Even if a chemical isn’t on an official list, if its SDS flags it as a carcinogen or reproductive toxin, treat it as a PHS.

How often should I check my fume hood’s airflow?

Fume hoods must be certified annually by a qualified technician to ensure airflow meets minimum standards: 100 feet per minute for general use, 150 feet per minute for Particularly Hazardous Substances. In addition, labs should perform a quick visual and functional check before each use-look for visible airflow, listen for the fan, and ensure the sash is at the correct height. If the hood is noisy, rattling, or the airflow feels weak, shut it down and report it immediately. Never use a hood that hasn’t been certified in the last 12 months.

Can I use the same gloves for all chemicals?

No. Glove material matters. Nitrile resists many solvents but breaks down with acetone. Neoprene works for acids and bases but not ketones. Latex offers almost no protection against lab chemicals. Always consult the SDS Section 8 or a glove compatibility chart before selecting gloves. A 2023 audit found nearly half of glove failures were due to using the wrong material. When in doubt, double-glove using different materials for layered protection.

Why are quarterly safety drills more effective than annual training?

Because safety isn’t knowledge-it’s habit. Quarterly drills reinforce muscle memory: where the spill kit is, how to activate the emergency shower, how to evacuate. A 2021-2023 study across 12 University of California campuses showed labs with quarterly drills had 63.8% fewer reportable incidents than those with annual training. Annual training is forgotten. Quarterly drills become routine. People remember what they do, not what they hear.

What’s the biggest mistake labs make with chemical storage?

The biggest mistake is storing incompatible chemicals together. Acids with bases, oxidizers with flammables, water-reactive materials near sinks-these combinations can cause fires, explosions, or toxic gas releases. A 2022 Triumvirate audit found that 42.7% of lab inspections had gaps in secondary containment or improper segregation. Always follow NFPA 400 segregation rules. Use color-coded cabinets, label everything, and maintain a live inventory. If you can’t find a chemical in your system, you can’t manage its risk.